Electrochemical separation technology group

2. Brief Introduction

3. Introduction of The Group Director

Name: Dr. Prof. Haitao Feng

Major: Group Leader

Tel: +86 0971-6280087

E-mail: fenght@isl.ac.cn

Brief CV:

Prof. Feng has served as the Deputy Director of the Qinghai Institute of Salt Lake, Chinese Academy of Sciences, and as the Director of the Qinghai Engineering Technology Centre for the Comprehensive Utilization of Salt Lake Resources. He is also the part-time Vice-Chairman of the Qinghai Science and Technology Association. Prof. Feng has been recognized as a leading talent in the Qinghai Kunlun High-end Innovation and Entrepreneurship Talent program, and has received multiple accolades, including the Outstanding Engineer from the Qinghai Science Achievement Award, the Outstanding Professional and Technical Talent Award from Qinghai Province, and the title of Outstanding Youth in the 40 Years of Development of China's Inorganic Salt Industry.

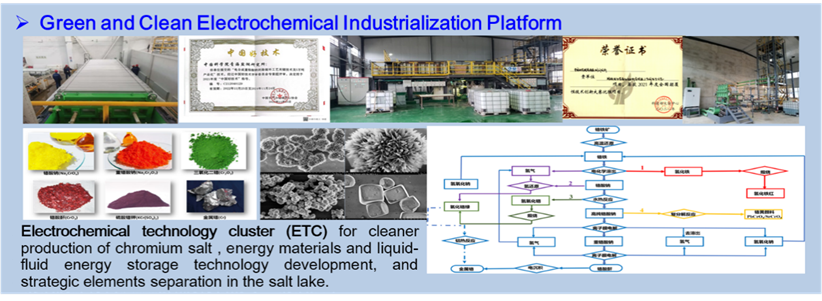

His research primarily focuses on electrochemical separation and electrochemical energy storage. He has made significant contributions to chrome salt clean technology, proposing a cluster of electrochemical-based clean production processes that encompass three major processes and four primary products. This innovative technology offers mild reaction conditions, high utilization efficiency, controllable processes, low emissions of waste and gases, and technological connectivity. His research is closely integrated with actual production, resulting in the industrialization of scientific outcomes, including the establishment of sodium bichromate production line with a capacity of 50,000 tons per year, and two demonstration lines for the production of sodium chromate and chromic anhydride.

Prof. Feng has led 22 scientific research projects, published 21 academic papers, been granted 20 invention patents, achieved 6 scientific and technological recognitions in Qinghai Province, and contributed to the development of 3 local standards in the province. Additionally, he serves on the editorial board of Salt Lake Research, a member of the Professional Committee of Inorganic Acid and Alkali Salts of the China Chemical Industry Society, and holds the positions of vice president of the Qinghai Salt Lake Resources Comprehensive Utilization Technology Innovation Centre and vice president of the Qinghai Standardization Association.

4. Group members

(1) Staffs

(2) Ph.D. Students

(3) Master’s Degree Students

5. Research Projects

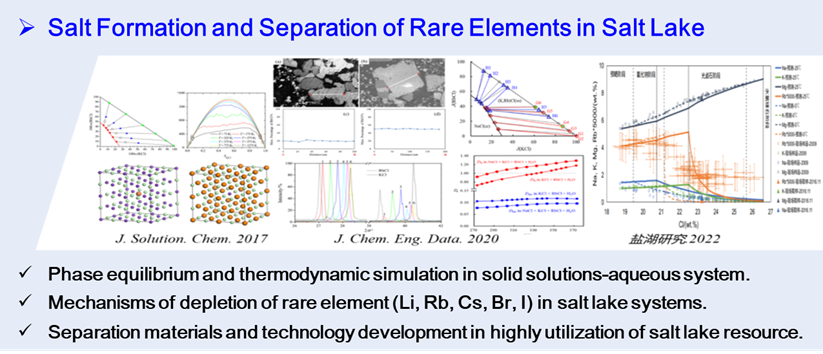

1. Formation of boric acid and ammonium-potassium carnallite complex salts during evaporation and crystallization of water from the South Yishan Oilfield, Joint Funds of the National Natural Science Foundation of China, Cultivation Project, 2017.1−2019.12.

2. Research on phase equilibrium in the comprehensive utilization of rubidium-potassium associated resources in Charkhan Salt Lake, Joint Funds of the National Natural Science Foundation of China, Cultivation Project,, 2015.01−2017.12.

3. Structural modification of substituted phenolic extractants in the extraction of rubidium from salt lake brine, Young Scientists Fund of the National Natural Science Foundation of China, 2015.01−2017.1.

4. Research on Freezing Salt Formation Law of Dachaidan Brine, General Program of National Natural Science Foundation of China. 2013.01−2016.12.

5. Research on key technology of lithium enrichment from oilfield water as raw material, subtopic of Qinghai Province Major Science and Technology Special Project, 2019.01−2022.12.

6. Green and clean chrome chemical technology and industrialization demonstration, Qinghai Province Major Science and Technology Special Project, 2016.08−2020.12.

7. Research and application of strontium micro-alloying in high magnesium aluminium alloy, Qinghai Provincial Achievement Transfer and Transformation Project, 2021.01−2023.12.

8. Applied basic research on the preparation of 3N grade high purity rubidium chloride from potassium chloride of salt lake, Qinghai Province Applied Basic Research Program, 2021.01−2023.12.

9. Applied basic research on new process of preparing sodium chromate from electrochemical oxidation of ferric chromium, Qinghai Province Applied Basic Research Program, 2017.06−2019.12.

10. Research on rubidium chloride cogeneration process in the production process of one million tonnes of potassium chloride in Charkhan, Western Light Young Scholars Class A Talent Programmed of CAS, 2021.01−2023.12.

11. Research and development of green and clean preparation process of chromium trichloride applicable to ferrochromium liquid flow battery, commissioned by the enterprise, 2023.1−2024.12;

12. Electrosynthesis of chromic anhydride process pilot and industrialization project, entrusted by the enterprise, 2018.04−2020.12.

13. Mechanistic study of the phase depth separation for rubidium-cesium using the 2H3BO3·3CsCladducts, Youth Fund of Qinghai Province Applied Basic Research Program, 2024.01−2026.12.

14. Construction of (phenyl)boronic/boric acid-based adducts and their application in the deep separation of potassium, rubidium and cesium. Special Research Assistant Program of CAS, China, 2024.01−2026.12.

15. Differences phase configuration of (phenyl)boronic/boric acid ligand adduct and their mechanistic study for rubidium-cesium depth separation, Young Scientists Fund of the National Natural Science Foundation of China, 2024.01−2026.12.

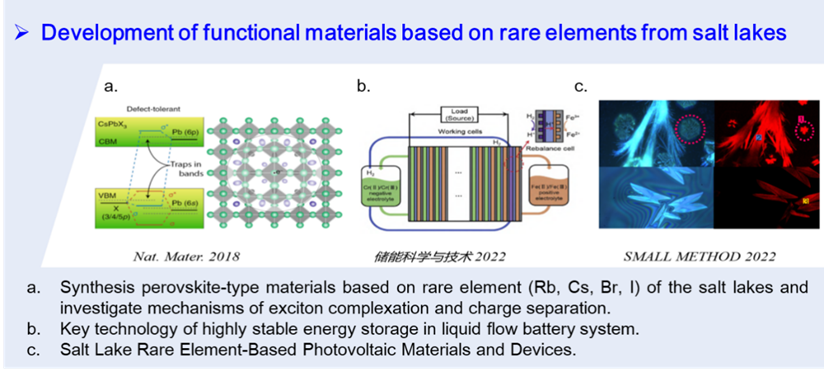

16. Applied fundamental study of crystal species-induced thermodynamic phase stability of formamidine-based perovskite, General Fund of Qinghai Province Applied Basic Research Program. 2024.01−2026.12.

17. Interlayer controlled graphene oxide separation membrane for precise separation of Li+/Na+, K+ and ion migration mechanisms, Qinghai Province Applied Basic Research Program. 2024.01−2026.12.

6. Publications

(1) Papers

1. Q. Li, B. Li*, S. Li, Y. Dong, D. Gao, Z. Niu, W. Li, H. Feng*. In-situ synthesis of CrOx(OH)3−2x for synchronous adsorption of Si and V from high concentration Cr(VI) solution and converted to excellent Cr2O3 pigment. Separation and Purification Technology, 2023, 309, 122973.

2. X. Li, B. Li*, Y. Dong, Z. Niu, D. Gao, H. Feng*, W. Li. Clean removal of silicon(IV) and vanadium(V) from high-concentration chromium(VI) solutions based on trivalent chromium green conversion in chromate production processes. Journal of Cleaner Production, 2023, 423, 138722.

3. B. Li, P. Han, B. Zhang, H. Feng*, W. Li, Y. Dong. A concise and mild green synthetic route of sodium chromate through ferrochrome electrochemical oxidation and in-situ purification. Journal of Hazardous Materials, 2020, 387, 121699.

4. D. Gao*, D. Li, B. Hu, W. Li. Solid–Aqueous Phase Equilibria in the Quaternary NaCl + KCl + RbCl + H2O System: Thermodynamic predictions and experimental verifications at 298.15 K. Journal of Chemical & Engineering Data, 2020, 65(10), 4837−4844.

5. D. Gao*, D. Li, B. Hu, W. Li. Phase diagram of the NaCl + RbCl + H2O system. Journal of Chemical & Engineering Data, 2017, 62(3): 1063−1067.

6. Z. Zhuang. Construction and application of solid-liquid phase equilibrium thermodynamic model for the containing boric acid and chloride brine. Changsha: Central South University, doctoral dissertation, 2022. (The thermodynamic modeling of Li+, Na+, K+, Rb+, Cs+, NH4+, Mg2+, Ca2+, Sr2+ // Cl−–H3BO3−H2O systems was accomplished. https://www.islec.net/news/)

7. Z Yang*, Dong Y P*, Li W, Liu X, Feng H T. Effect of Sr element on hot deformation behavior and microstructure of Al-4.6Mg alloy[J]. Journal of alloys and compounds. 2022, 930: 167300.

8. J. Han, Li B, Nai X Y, Wu P, Zhang B, Dong Y P, Li W, Liu X*. Facile strategy for the construction of a robust underbrine superoleophobic membrane for highly efficient oil-brine separation, Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 638: 128247.

9. Z. Zhuang, D. Li*, Y. Fan, D. Gao, D. Zeng*. Solubility isotherms determination of the H3BO3 + CsCl + H2O system at T = (273.15, 298.15, 323.15,348.15 and 363.15) K and thermodynamic modeling. The Journal of Chemical Thermodynamics. 2022, 170: 106763.

10. Z. Zhuang, D. Li*, D. Zeng*, D. Gao, Y. Dong Solubility isotherms determinations at T = (273.15, 298.15, 323.15, 348.15 and 363.15) K and thermodynamic modeling of the H3BO3 + SrCl2 + H2O system. Journal of Solution Chemistry. 2020,50(5), 771‒791.

11 Z. Zhuang, D. Li*, J. Lei, D. Gao, D. Zeng*. Solubility isotherm determination of the H3BO3 + RbCl + H2O and H3BO3 + NH4Cl + H2O systems at T = 273.15, 298.15, 323.15, 348.15, and 363.15 K and thermodynamic modeling. Journal of Chemical & Engineering Data, 2022, 67(5), 1267‒1275.

12 Y. Cui, Y. Xu, X. Liu, Y. Li*, B. Wang*, Y. Dong, W. Li, S. Lei*. Field-induced single-ion magnetic behavior in two mononuclear cobalt(II) complexes, Chemistry an Asian Journal, 2019, 14, 2620.

13. Y. Cui, Y. Ding, S. Molina, Y. Li*. A mixed-valence Cu-II/Cu-I coordination polymer based on bridged thiocyanate and in situ formed di(N-heterocyclic) sulfide: Synthesis, structure, and magnetic properties, Journal of Molecular Structure, 2021, 1241, 130623.

14. Z. Yang*, Y Dong*, W Li, X Liu, H. Feng. Effect of Sr Microalloying on Microstructure and Corrosion Resistance of Al-4.6 Mg Alloy. Materials and Corrosion, 2023, 74: 1101‒1115.

(2) Patents

1.Direct preparation of trivalent chromium compounds by electrochemical oxidation of chromium iron, ZL. 202211671767.8.

2. Method and device for preparing trivalent chromium salt by electrochemical oxidation of ferrochrome in acidic system, ZL. 202211671770.x.

3. A preparation method of spherical nano chromium trioxide, ZL. 201911187309.5.

4. A preparation method of ammonium chromate crystals, ZL. 201911187614.4.

5. A method of extracting rubidium from high potassium magnesium brine, ZL. 202110690567.6.

6. Copper chromium black, its hydrothermal synthesis method and application, ZL. 202111351148.6.

7. Copper chromium black, its low temperature preparation method and application, ZL. 202111344669.9.

8. Method of preparing lithium sulphate from crude lithium sulphate salt ore of a salt lake, ZL. 201810669026.3.

9. Method of refining lithium sulphate salt crude ore, ZL. 201510881141.3.

10. Preparation method of high purity nano chromium trioxide, ZL. 201910439129.5.

11. Method of preparing iron oxide red using ferrochrome, ZL. 201710801316.4.

12. Method of preparing chromium oxide green using ferrochrome, ZL. 201710801279.7.

13. Device and method for preparing high concentration chromate solution, ZL. 201710802293.9.

14. Method of preparing chromic anhydride using ferrochrome, ZL. 201710802271.2.

15. Method of preparing high purity chromate using ferrochrome, ZL. 201710801836.5.

16. Method of preparing chromium oxide green using ferrochrome, ZL. 201710801830.8.

17. Method for the combined production of chromium oxide green, iron oxide red and high purity chromate by electrolysis of ferrochrome, ZL. 201710801801.1.

18. Method of preparing dichromate using ferrochrome, ZL. 201710802268.0.

19. Device and method for preparing sodium chromate solution using electrolysis, ZL. 201310672022.8.

20. Device and method for preparing potassium chromate solution using electrolysis, ZL. 201310674678.3.

21. A method of producing sodium dichromate by cation membrane electrolysis, ZL. 201310525165.6.

22. A method of extracting rubidium and cesium salts, ZL. 201410056879.1.

23. A method of determining trace ions in chromium salt, ZL. 201310342781.8.

24. Continuous preparation device of sodium dichromate crystalline solution, ZL. 201020261741.2.

25. Method of preparing sodium dichromate dihydrate by ion membrane electrolysis, ZL. 200910001674.2.

(3) Monograph

1. W. Li, Y. Dong, P. Song, et al. Salt lake brine resources development and utilization. Beijing, Chemical Industry Press, 2012.

2. X. Zeng (chief compiler), Y Dong (vice chief compiler), et al. Boron fluoride compound. Beijing, Chemical Industry Press, 2011.

3. X. Zeng (chief compiler), Y Dong (vice chief compiler), et al. Production and application of boron compounds, 1ed. Beijing, Chemical Industry Press, 2008.

4. X. Zeng (chief compiler), Y Dong (vice chief compiler), et al. Production and application of boron compounds. 2ed. Beijing, Chemical Industry Press, 2014.

7. Awards and Honors

1. ‘Clean Process and Efficient Utilization of Chromium Salt’, Qinghai Salt Lake Research Institute, Chinese Academy of Sciences, was awarded the Advanced Group of Qinghai Province for Promoting Achievement in High-Quality Development, 2023.

2. ‘Research on Rubidium Chloride Cogeneration Process in the Production of One Million Tonnes of Potassium Chloride in Charkhan’, Excellent in the Final Evaluation of the Selected Participants of ‘Light of the West’ Talent Cultivation Program in 2019, 2024.

3. ‘Key Technology of Closed-Circuit Cycle Process for Electrosynthesis of Sodium Dichromate and Industrialization of 50,000 Tons of Sodium Dichromate’ was awarded the title of Good Technology of China, 2022.

4. ‘Research and Development and demonstration of Chromium Salt Preparation Process by Ferrochrome Electrochemical Oxidation Technology’ won the title of National Disruptive Innovation Technology Competition, 2021.

5. ‘Clean Production of Ionic Membrane Chromic Anhydride with an Annual Production Capacity of 10,000 Tons’ won the 2018‒2020 Inorganic Chemical Science and Technology Award-Technology Innovation Award, 2020.

6. ‘New Process of Electrochemical Synthesis of Sodium Dichromate and Demonstration of 50,000 Tons Industrialization’ won the 8th China Technology Market Golden Bridge Award, 2016.

7. ‘New process of electrochemical synthesis of sodium dichromate and demonstration of 50,000 tones industrialization’ won the 2012-2014 Inorganic Chemical Science and Technology Award-Technological Innovation Award, 2014.