China is a large agricultural country, and salt lake potassium resources are an important strategic resource. However, the promotion of potassium by-products in the salt lake area severely restricts the balance and sustainable development of local resources. The by-product magnesium chloride is mainly deposited in the form of bischofite or discharged into the salt lake in the form of old brine. This not only causes huge waste of magnesium resources in the salt lake, but also affects the resource occurrence state and development environment of the lake area. It has become a "bottleneck" that restricts the efficient and sustainable development of resources such as potassium, lithium and boron in the salt lake.

At present, magnesium chloride in salt lakes is mainly used for the production of magnesium hydroxide, magnesium metal and magnesium alloys, magnesium compound whiskers, etc., but the annual utilization rate is less than 1 million tons. However, magnesium chloride can be directly used for magnesium oxychloride cement (MOC) without finishing, and concrete with MOC as gel phase can “directly” consume “rich” magnesium chloride, which is widely used in construction and transportation. It provides an effective way to solve the problem of large-scale utilization of magnesium chloride.

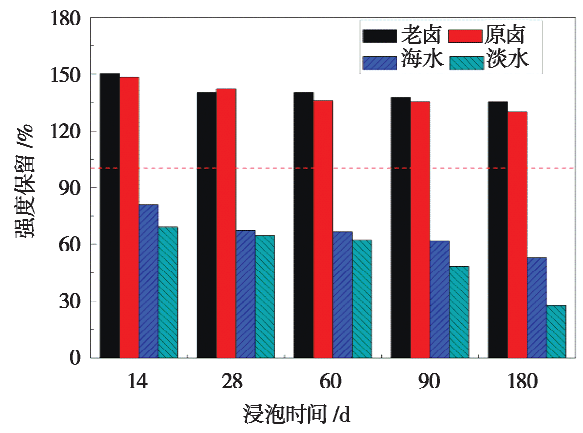

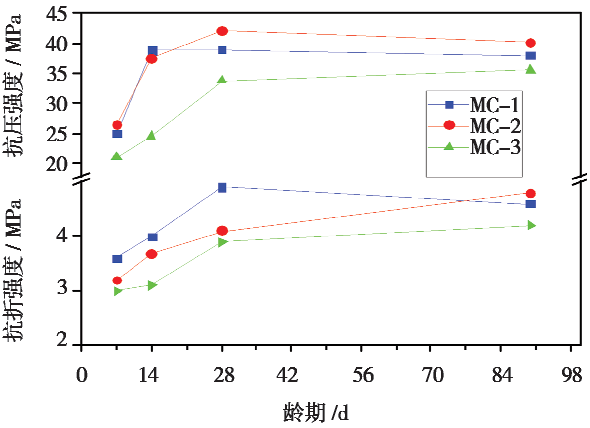

In response to the above problems, Professor Xiao Xueying Research Team, from Salt Lake Resources Chemistry Laboratory, through soaking (old halogen, raw brine and seawater) experiments, it was found that the compressive strength and flexural strength of the MOC specimens in the three immersion schemes were well preserved. From practical application, MOC concrete has great development prospects and potential in the high-cold and high-salt areas in the west, which not only promotes the sustainable development and utilization of magnesium resources in salt lakes, but also broadens the building materials for alpine and high-salt areas. For details, see Salt Lake Research, No. 3, 2018, “Research Highlights”, page 7-13.

Strength retention phase of MOC specimens immersed in 4 different brine environments

Mechanical performance curve of MOC concrete