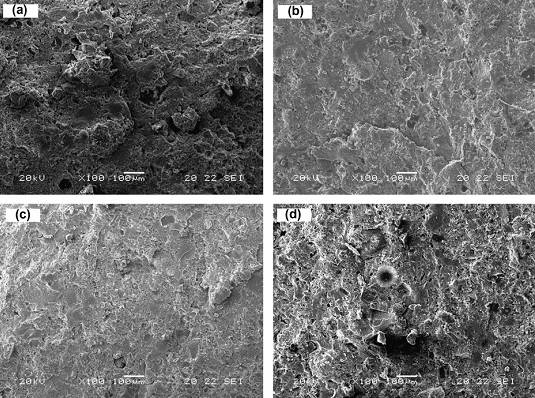

This paper presents the results of an experimental investigation on compressive strength of granite waste fly ash magnesium oxychloride cement (GFMOC). Various GFMOC specimens were prepared with 23°Bé or 25°Bé brine and different proportions of granite fragment (GF) or granite sludge (GS) ranging from 0% (for the control mixture) to 40% of magnesia weight. Compression tests were conducted at the age of 3, 7, and 28 days. The hydration products and paste microstructure were analyzed by XRD and SEM, respectively. The results demonstrated that the water absorption and filling role of the fine particles of granite waste in GFMOC slurry are favorable for 5 Mg(OH)2⋅MgCl2⋅8H2O (P5) and dense microstructure, respectively. The quantity ratio of P5 to Mg(OH)2 (MH) and microstructure are important factors responsible for the compressive strength of GFMOC. The incorporation of granite wastes as aggregate can increase the compressive strength of fly ash magnesium oxychloride cement (FMOC).

SEM micrograph of the control samples and the specimens with 30% GS at 28 days. (Photo from the original paper)